HOT DIP GALVANIZING (HDG) LONG LIVE SERVICES

Rabu, 16 Maret 2011

Kamis, 16 Desember 2010

GREY COATINGS ON HOT DIP GALVANIZED STEEL

INTRODUCTION

A common phenomenon with hot dip galvanized structural steel is the grey appearance of part or all of the coating after galvanizing, where the expectation of the customer is for the galvanized steel to be shiny. Grey coatings are often a cause of contention between galvanizers and their customers as a result. This File has been produced to explain the phenomenon of grey coatings, their cause and effect on the performance of hot dip galvanized steel.

WHY ARE SOME GALVANIZED COATINGS GREY

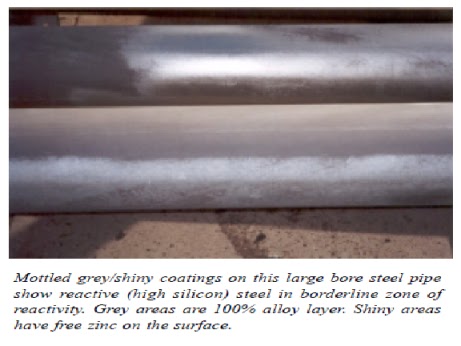

Hot dip galvanized coatings are the result of a metallurgical reaction between the zinc and the steel. This

reaction forms a series of zinc-iron alloys in the form of needle like crystals that grow from the steel’s

surface. With conventional galvanized coatings, the alloy layer makes up about 80% of the coating and the upper 20% of the coating is zinc. This surface layer gives produced the shiny appearance. Where this surface coating of free zinc is not present, the zinc-iron crystals are visible and it is the appearance of these that gives the coating matte silver or grey appearance. When the steel emerges from the galvanizing bath, the coating is always shiny. The appearance of the coating changes to grey as the residual heat from the galvanizing process allows the reaction between the steel and the zinc to continue until all the fee zinc on the surface is consumed, leaving the coating with 100% alloy layers.

WHAT CAUSES SOME STEELS TO PRODUCE GREY COATINGS?

The reaction between zinc and steel in the galvanizing process is a function of a number of factors. The

most significant of these with respect to grey coatings are:

1. The chemical composition of the steel

2. The steel section thickness

3. The galvanizing bath temperature

4. The cooling rate of the steel after galvanizing

Of these, the chemical composition of the steel is the most important. Two alloying elements in particular, silicon and phosphorus, will increase the reaction rate of the zinc with the steel. If the silicon content exceeds 0.20% or the combination of the percentage of silicon plus 2x the phosphorus level exceeds 0.25%, then the likelihood of grey coatings forming is increased. Most Australian-made steels are ‘galvanizer friendly’ in this respect with silicon and phosphorus levels controlled within acceptable limits. As about 35% of steel used in Australia is now imported, the variation in steel chemistry makes control of grey coatings a more difficult issue. The steel section thickness is a factor with relatively thick sections (over 20 mm) because the greater mass of steel retains heat longer. The zinc-iron reaction will continue even when the zinc has solidified (at 420 degrees C) as a solid-state reaction until the temperature falls below about 390 degrees C. For this reason, heavy plate fabrications will produce thicker, grey coatings regardless of the steel chemistry. The galvanizing bath temperature will only have an effect where it is possible to operate the galvanizing bath at above the normal 455 degrees C level. This can only be done in special ceramic lined galvanizing baths, as high operating temperatures will damage conventional steel galvanizing baths. The cooling rate of the steel after galvanizing can affect the coating appearance. Galvanized items that are air-cooled are more likely to develop grey or partly grey coating than items that are quenched immediately after withdrawal from the galvanizing bath. This occurs because the quenching halts the solid-state zinc iron reaction before all the free-zinc on the coating’s surface is consumed.

WHAT EFFECT DO GREY COATINGS HAVE ON COATING PERFORMANCE

Without exception, grey coatings are thicker than shiny galvanized coatings on equivalent steel sections. Australian and international galvanizing standards require that on structural sections over 6 mm in thickness, the minimum galvanized coating thickness is specified at 85 microns. Grey galvanized coatings are more typically almost double this thickness, and on heavier sections will frequently exceed 200 microns in thickness. As galvanized coating life is almost directly proportional to coating thickness, a significant increase in service life can be expected from these heavier coatings. The main problems associated with grey coatings are their aesthetic acceptability and the fact that the zinc-iron alloy layers are hard and inflexible, and may be prone to mechanical damage if subjected to impacts during transport and erection, where conventional shiny coatings have excellent resistance to quite severe impacts. One fringe benefit of grey coatings on galvanized steel is that they provide a good substrate for painting, because of the matte surface. BHP produces a galvanized sheet product called Zincanneal where the mill produced shiny galvanized coating is converted to a 100% alloy layer coating by post heat treatment to improve the paintability of the product for whitegoods manufacture.

A common phenomenon with hot dip galvanized structural steel is the grey appearance of part or all of the coating after galvanizing, where the expectation of the customer is for the galvanized steel to be shiny. Grey coatings are often a cause of contention between galvanizers and their customers as a result. This File has been produced to explain the phenomenon of grey coatings, their cause and effect on the performance of hot dip galvanized steel.

WHY ARE SOME GALVANIZED COATINGS GREY

Hot dip galvanized coatings are the result of a metallurgical reaction between the zinc and the steel. This

reaction forms a series of zinc-iron alloys in the form of needle like crystals that grow from the steel’s

surface. With conventional galvanized coatings, the alloy layer makes up about 80% of the coating and the upper 20% of the coating is zinc. This surface layer gives produced the shiny appearance. Where this surface coating of free zinc is not present, the zinc-iron crystals are visible and it is the appearance of these that gives the coating matte silver or grey appearance. When the steel emerges from the galvanizing bath, the coating is always shiny. The appearance of the coating changes to grey as the residual heat from the galvanizing process allows the reaction between the steel and the zinc to continue until all the fee zinc on the surface is consumed, leaving the coating with 100% alloy layers.

WHAT CAUSES SOME STEELS TO PRODUCE GREY COATINGS?

The reaction between zinc and steel in the galvanizing process is a function of a number of factors. The

most significant of these with respect to grey coatings are:

1. The chemical composition of the steel

2. The steel section thickness

3. The galvanizing bath temperature

4. The cooling rate of the steel after galvanizing

Of these, the chemical composition of the steel is the most important. Two alloying elements in particular, silicon and phosphorus, will increase the reaction rate of the zinc with the steel. If the silicon content exceeds 0.20% or the combination of the percentage of silicon plus 2x the phosphorus level exceeds 0.25%, then the likelihood of grey coatings forming is increased. Most Australian-made steels are ‘galvanizer friendly’ in this respect with silicon and phosphorus levels controlled within acceptable limits. As about 35% of steel used in Australia is now imported, the variation in steel chemistry makes control of grey coatings a more difficult issue. The steel section thickness is a factor with relatively thick sections (over 20 mm) because the greater mass of steel retains heat longer. The zinc-iron reaction will continue even when the zinc has solidified (at 420 degrees C) as a solid-state reaction until the temperature falls below about 390 degrees C. For this reason, heavy plate fabrications will produce thicker, grey coatings regardless of the steel chemistry. The galvanizing bath temperature will only have an effect where it is possible to operate the galvanizing bath at above the normal 455 degrees C level. This can only be done in special ceramic lined galvanizing baths, as high operating temperatures will damage conventional steel galvanizing baths. The cooling rate of the steel after galvanizing can affect the coating appearance. Galvanized items that are air-cooled are more likely to develop grey or partly grey coating than items that are quenched immediately after withdrawal from the galvanizing bath. This occurs because the quenching halts the solid-state zinc iron reaction before all the free-zinc on the coating’s surface is consumed.

WHAT EFFECT DO GREY COATINGS HAVE ON COATING PERFORMANCE

Without exception, grey coatings are thicker than shiny galvanized coatings on equivalent steel sections. Australian and international galvanizing standards require that on structural sections over 6 mm in thickness, the minimum galvanized coating thickness is specified at 85 microns. Grey galvanized coatings are more typically almost double this thickness, and on heavier sections will frequently exceed 200 microns in thickness. As galvanized coating life is almost directly proportional to coating thickness, a significant increase in service life can be expected from these heavier coatings. The main problems associated with grey coatings are their aesthetic acceptability and the fact that the zinc-iron alloy layers are hard and inflexible, and may be prone to mechanical damage if subjected to impacts during transport and erection, where conventional shiny coatings have excellent resistance to quite severe impacts. One fringe benefit of grey coatings on galvanized steel is that they provide a good substrate for painting, because of the matte surface. BHP produces a galvanized sheet product called Zincanneal where the mill produced shiny galvanized coating is converted to a 100% alloy layer coating by post heat treatment to improve the paintability of the product for whitegoods manufacture.

Rabu, 15 Desember 2010

Ten important reasons to use Hot Dip Galvanization

1 Competitive initial cost

Due to the fact that it is a highly mechanical process, fire galvanization in main aplications has a lower initial cost compared to other anti-corrosive coatings.

2 Lower maintenace cost

The lower initial cost and durability makes hot dip galvanization more versatile and less espensive to protect steel and cast iron for longer periods against atmospheric corrosion. In equipment or structures located in areas of difficult access, mountains or still with security restrictions (e.g. electrification towers), the increasing maintenance intervals decrease the expenditure and work interruptions. In many cases galvanization with hot

zinc may even turn maintenance necessary, but whem indispensable, there is no need for complex pretreaments.

3 Durability

The durability of products with undergo hot dip treatment is directly proportional to the zinc coating desity and protects against aggressions to the atmosphere. It generally last 10 years in industrial environment, 20 years at the seaside, and more than 25 years in rural areas.

4 Reliability

The hot dip galvanization process is simple, direct and totally controlled. The density of the coating is uniform, can be determined in advance and is of simple specification. 5 Swiftness of the process (and utilization) By applying hot dip galvanization, a complete coating of a piece is achieved in a few minutes, whereas another process would take hours or even days. (The modern lines of continuous galvanization can produce, for example, 500 m2/minute of metal sheets with excellent coating quality). Immediately after galvanization, the piece is ready for use without any need for preparing its surface, retouching or painting.

6 Coating resistance

The process of immersion in hot zinc process produces a coating metallurgically linked to the steel by the formation of Fe-Zn and Zn layers. No other coating process presents these characteristic, producing hot dip galvanized products with a great resistance to mechanical failures during manipulation, storage, transpostation and installation. Besides that, the coating's hardness makes it particularly adequate in applications where abrasion could be a problem.

7 Complete and perfect coating

The immersion of the piece in zinc covers internal and external surfaces, edges and narrow cracks, not provided by other treatments. In addition, the hot zinc process Why Galvanize? maintains the density of the coating in edges and borders, which does not occur in other types of coating Processes.

8 Three ways of protection

The galvanization process steel in three ways:

1. The zinc coating suffers a minimal environment corrosion, therefora having a long and predictable lifetime.

2. The coating is corroded thus proportioning a cationic protection to the small areas of the piece exposed to the atmosphere, in most cases due to friction, cuts or accidental damages.

3. If the damaged area is large, the cationic zinc protection inhibits the spreading of the corrosion over the coating.

9 Easiness of inspection

A product which underwent galvanization can be easily inspected. The nature of the process is such that if the coating appears to be continuous and perfect, is really is. Apart from this fact, the density of the coating can be checked at any time through magnetic equipment or non-damaging tests.

10 Diversification of application

The mechanical resistance of steels added to the zinc resistance, makes the galvanized product an inexpensive and versatile means for a great number of applications.

Due to the fact that it is a highly mechanical process, fire galvanization in main aplications has a lower initial cost compared to other anti-corrosive coatings.

2 Lower maintenace cost

The lower initial cost and durability makes hot dip galvanization more versatile and less espensive to protect steel and cast iron for longer periods against atmospheric corrosion. In equipment or structures located in areas of difficult access, mountains or still with security restrictions (e.g. electrification towers), the increasing maintenance intervals decrease the expenditure and work interruptions. In many cases galvanization with hot

zinc may even turn maintenance necessary, but whem indispensable, there is no need for complex pretreaments.

3 Durability

The durability of products with undergo hot dip treatment is directly proportional to the zinc coating desity and protects against aggressions to the atmosphere. It generally last 10 years in industrial environment, 20 years at the seaside, and more than 25 years in rural areas.

4 Reliability

The hot dip galvanization process is simple, direct and totally controlled. The density of the coating is uniform, can be determined in advance and is of simple specification. 5 Swiftness of the process (and utilization) By applying hot dip galvanization, a complete coating of a piece is achieved in a few minutes, whereas another process would take hours or even days. (The modern lines of continuous galvanization can produce, for example, 500 m2/minute of metal sheets with excellent coating quality). Immediately after galvanization, the piece is ready for use without any need for preparing its surface, retouching or painting.

6 Coating resistance

The process of immersion in hot zinc process produces a coating metallurgically linked to the steel by the formation of Fe-Zn and Zn layers. No other coating process presents these characteristic, producing hot dip galvanized products with a great resistance to mechanical failures during manipulation, storage, transpostation and installation. Besides that, the coating's hardness makes it particularly adequate in applications where abrasion could be a problem.

7 Complete and perfect coating

The immersion of the piece in zinc covers internal and external surfaces, edges and narrow cracks, not provided by other treatments. In addition, the hot zinc process Why Galvanize? maintains the density of the coating in edges and borders, which does not occur in other types of coating Processes.

8 Three ways of protection

The galvanization process steel in three ways:

1. The zinc coating suffers a minimal environment corrosion, therefora having a long and predictable lifetime.

2. The coating is corroded thus proportioning a cationic protection to the small areas of the piece exposed to the atmosphere, in most cases due to friction, cuts or accidental damages.

3. If the damaged area is large, the cationic zinc protection inhibits the spreading of the corrosion over the coating.

9 Easiness of inspection

A product which underwent galvanization can be easily inspected. The nature of the process is such that if the coating appears to be continuous and perfect, is really is. Apart from this fact, the density of the coating can be checked at any time through magnetic equipment or non-damaging tests.

10 Diversification of application

The mechanical resistance of steels added to the zinc resistance, makes the galvanized product an inexpensive and versatile means for a great number of applications.

Selasa, 14 Desember 2010

The typical characteristics of appearance:

There are several characteristics to the appearance to include; dull gray color, rust stains, blisters, texture

(smooth, rough), lumps, pimples, bare spots, bulky white deposit, and dark spots. The following information

will tell more about these different appearance issues:

1. Dull gray coating: This type of coating is normally acceptable and is caused by growth of the zinc iron alloy layers through to the surface of the galvanized coating .

2. Rust stains: The rust stains are acceptable when present as a surface stain, this is usually caused by contact with or drainage with other corroded steel surfaces.

3. Blisters: Small intact blisters in the coating are acceptable and are usually due to absorption of hydrogen by the steel during the pickling process being expelled as a result of the heat put off by the galvanizing process.

4 General roughness and thick coatings: General roughness of the outer material is normally acceptable as long as not otherwise agreed on with the consumer. The cause of rough galvanized coatings is usually a result from uneven growth of zinc iron alloys because of the composition or surface condition of the steel.

5. Lumpiness and runs: Lumps are normally acceptable unless otherwise specified and are caused by uneven drainage. Lumps and runs have no impact on the coating life.

6. Pimples: Pimples are grounds for rejection depending on size and extent. Pimples are caused by inclusions of dross in the coating. Dross, which is a zinc iron alloy particles has a similar corrosion rate to the galvanized coating and its presence as finely dispersed pimples is not objectionable. Gross dross inclusions may be

grounds for rejection as they tend to embrittle the coating.

7. Bare spots: Bare spots are generally acceptable if small in area and suitably repaired, depending on the nature of the product. Some reasons for bare spots are faulty processing, rolling defects, laminations and nonmetallic impurities rolled into the surface.

8. Wet storage stain or bulky white deposit: A bulky white or gray deposit, known as wet storage stain may form on the surface of closely stacked freshly galvanized articles which become damp under poorly ventilated conditions during storage or were left damp as a result of the product not being dry before storing. reason for wet material being stored is an insufficient wax concentration, either to much was or to little.

Appearance

A galvanized coating is normally smooth, continuous and free from gross surface imperfections and inclusions. While the heavy zinc coating on general galvanized articles should be smooth and continuous it cannot be compared for surface smoothness to continuously galvanized sheet steel or wire since these are produced by processes which permit close control of coating thickness and appearance.

Differences in the lustre and colour of galvanized coatings do not significantly affect corrosion resistance and the presence or absence of spangle has no effect on coating performance. As discussed under ‘Dull grey coating’ below, uniform or patchy matt grey galvanized coatings give equal or better life than normal bright or spangled coatings. It is recommended that inspection of galvanized work should be carried out by a designated party at the galvanizer’s works in accordance with the following guidelines, and tested when

necessary as detailed under ‘Non-destructive testing for coating thickness’.

Variations in appearance and their relationship to coating quality Variations in appearance of galvanized coatings listed below and their influence on coating quality are discussed on following pages.

Dull grey coating

General comment: Acceptable. A dull grey appearance is caused by growth of the zinc-iron alloy layers through to the surface of the galvanized coating. Grey coatings may appear as localized dull patches or

lacework patterns on an otherwise normal galvanized coating or may extend over the entire surface.

Dull grey coatings usually occur on steels with relatively high silicon content which are highly reactive to molten zinc as discussed under ‘Composition of steel’.

Welds made with steel filler rods containing silicon may also produce localised grey areas in an otherwise normal galvanized coating.

Welds made with steel filler rods containing silicon may also produce localised grey areas in an otherwise normal galvanized coating.

Dull grey coatings are often thicker than the normal bright or spangled coatings and therefore give longer life. It is rarely possible for the galvanizer to minimise or control the development of dull grey coatings which is dependent basically on steel composition.

Blisters

General comment: Small intact blisters acceptable.

Extremely rare. Small blisters in galvanized coatings are due to hydrogen absorbed by the steel during pickling being expelled as a result of the heat of the galvanizing process. Their occurrence is due to the nature of the steel and is outside the control of the galvanizer. Blisters do not reduce the corrosion resistance of the coating.

Rust staining on the surface of galvanized coatings is usually due to contact with or drainage from other corroded steel surfaces. Steel filings or saw-chips produced during erection and fabrication operations should be removed from galvanized surfaces to prevent possible localised rust staining. Rust staining may also be caused by the weeping of pickling acid from seams and joints causing damage to the galvanized coating, and in such cases requires a modification in design as discussed under ‘Overlapping surfaces’.

Rust staining on the surface of galvanized coatings is usually due to contact with or drainage from other corroded steel surfaces. Steel filings or saw-chips produced during erection and fabrication operations should be removed from galvanized surfaces to prevent possible localised rust staining. Rust staining may also be caused by the weeping of pickling acid from seams and joints causing damage to the galvanized coating, and in such cases requires a modification in design as discussed under ‘Overlapping surfaces’.

A thin brown surface staining sometimes occurs in service when the galvanized coating comprises entirely zinc-iron alloys as discussed under ‘Dull grey coating’. Staining arises from corrosion of the iron content of the zinciron alloy coating and is therefore outside the control of the galvanizer. It has no effect on the corrosion resistance of th coating. Long term exposure testing has shown that the corrosion resistance of zinc-iron alloys is similar to that of normal galvanized coatings.

General roughness and thick coatings on welds.

General comment: Acceptable, unless otherwise agreed.

Rough galvanized coatings usually result from uneven growth of zinc-iron alloys because of the composition or surface condition of the steel. Where welding electrodes containing silicon have been used, the galvanized coating on the weld area may be thicker than normal and may also be brittle. Rough coatings of this type are usually thicker than normal and therefore provide longer protective life. General roughness may also be caused by over-pickling, prolonged immersion in the galvanizing bath, or excessive bath temperature, factors which are frequently dictated by the nature of the work and may be beyond the control of the

Rough galvanized coatings usually result from uneven growth of zinc-iron alloys because of the composition or surface condition of the steel. Where welding electrodes containing silicon have been used, the galvanized coating on the weld area may be thicker than normal and may also be brittle. Rough coatings of this type are usually thicker than normal and therefore provide longer protective life. General roughness may also be caused by over-pickling, prolonged immersion in the galvanizing bath, or excessive bath temperature, factors which are frequently dictated by the nature of the work and may be beyond the control of the

galvanizer. In architectural applications where a rough finish is aesthetically or functionally unacceptable, the steel composition and surface preparation should be closely specified and the galvanizer consulted at an early stage. It is rarely possible for the galvanizer to effect any later improvement.

Lumpiness and runs

General comment: Acceptable unless otherwise specified.

Australian/New Zealand Standard 4680 ‘Hot dip galvanized (zinc) coatings on fabricated ferrous articles’ demands that a galvanized coating shall be ‘smooth’ but points out that smoothness is a relative term and that coatings on fabricated articles should not be judged by the same standards as those applied to continuously galvanized products such as sheet steel and wire, since these are produced by processes which permit a high degree of control over coating thickness and appearance. Lumps and runs arising from uneven

drainage are not detrimental to coating life. When zinc drainage spikes are present on galvanized articles

drainage are not detrimental to coating life. When zinc drainage spikes are present on galvanized articles

and their size and position is such that there is a danger they may be knocked off in service removing the coating down to the alloy layers, they should be filed off by the galvanizer and, where necessary, the coating should be repaired as described. For architectural applications the galvanizer can sometimes

achieve a smoother finish than the normal commercial coating, depending on the shape and nature of the product. The steel should be carefully specified and the galvanizer consulted at the design stage and advised when the order is placed. Extra cost may be involved.

Pimples

General comment: May be grounds for rejection depending on size and extent.

General comment: May be grounds for rejection depending on size and extent.

Pimples are caused by inclusions of dross in the coating. Dross, which comprises zinc-iron alloy particles, has a similar corrosion rate to the galvanized coating and its presence as finely dispersed pimples is not objectionable. Gross dross inclusions may be grounds for rejection as they tend to embrittle the coating.

Bare spots

General comment: Acceptable if small in area and suitably repaired, depending on the nature of the product.

Small localised flaws up to about 3 mm wide in a galvanized coating are usually self-healing because of the cathodic protection provided by the surrounding coating as discussed under Cathodic Protection .

They have little effect on the life of the coating. Australian/New Zealand Standard 4680 Appendix E

They have little effect on the life of the coating. Australian/New Zealand Standard 4680 Appendix E

‘Renovation of damaged or uncoated areas’ specifies that “... the sum total of the damaged or uncoated areas shall not exceed 0.5% of the total surface area or 250cm2, whichever is the lesser, and no individual damaged or uncoated areas greater than 40cm2. However, as an exception, uncoated areas greater than 40cm2, which have been caused by unavoidable air locks during the galvanizing operation, shall be repaired.” Repair methods which accord with AS/NZS 4680 Appendix E are detailed.

Bare spots may be caused by under-preparation by the galvanizer and by a number of factors outside his control, and for which he cannot be responsible, including the presence of residual welding slags, rolling defects such as laps, folds and laminations in the steel, and non-metallic impurities rolled into the steel surface.

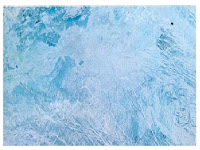

Wet storage stain or bulky white deposit

General comment: Not the galvanizer’s responsibility unless present before first shipment. Acceptable if non-adherent deposit is removed and the coating meets coating mass requirements. A bulky white or grey deposit, known as wet storage stain may form on the surface of closely stacked freshly galvanized

articles which become damp under poorly ventilated conditions during storage or transit. In extreme cases, the

protective value of the zinc coating may be seriously impaired but the attack is often very light despite the bulky appearance of the deposit. Initiation and development of wet storage staining on new

galvanized surfaces is readily prevented as detailed by attention to conditions of storage and transport and by

application of a chromate passivation treatment. Where the surface staining is light and smooth without

growth of the zinc oxide layer as judged by lightly rubbing fingertips across the surface, the staining will gradually disappear in service and blend in with the surrounding zinc surface as a result of normal weathering.

When the affected area will not be fully exposed in service, particularly on the underside of steelwork and in

condensation areas, or when it will be subject to a humid environment, wet storage staining must be removed as detailed below, even if it is superficial. Removal is necessary to allow formation of the basic zinc carbonate film which normally contributes to the corrosion resistance of galvanized

coatings. Medium to heavy buildup of white corrosion product must be removed to allow formation of a basic zinc carbonate film in service. Light deposits can be removed by brushing with a stiff bristle brush. Heavier deposits can be removed by brushing with a 5 percent solution of sodium or potassium dichromate with the addition of 0.1 percent by volume of concentrated sulphuric acid. This is applied with a stiff brush and left for about 30 seconds before thorough rinsing and drying. A check should be made to ensure that the coating

thickness in affected areas is not less than the minimum specified in relevant standards for the various classes of galvanized coatings as detailed. In extreme cases, where heavy white deposit or red rust has been allowed to form as a result of prolonged storage under poor conditions, corrosion products must be removed by thorough wire brushing and the damaged area repaired as detailed.

Dark spots/Flux staining

General comments: Acceptable if flux residues have been removed.

Smuts of dirt may be picked up on the surface of the galvanized coating from floors and trucks or from contact with other articles. These smuts are readily washed off to reveal a sound coating and are not harmful.

Where a flux blanket is used in the galvanizing process, stale flux may adhere to the surface of the work during immersion and appear as a black inclusion in the coating. Such inclusions tend to pick up moisture forming a corrosive solution and coatings containing them should be rejected. Black stains or deposits of flux picked up on the surface. the object is withdrawn from galvanizing the bath do not warrant rejection provided the underlying coating is sound and the deposit is removed.

(smooth, rough), lumps, pimples, bare spots, bulky white deposit, and dark spots. The following information

will tell more about these different appearance issues:

1. Dull gray coating: This type of coating is normally acceptable and is caused by growth of the zinc iron alloy layers through to the surface of the galvanized coating .

2. Rust stains: The rust stains are acceptable when present as a surface stain, this is usually caused by contact with or drainage with other corroded steel surfaces.

3. Blisters: Small intact blisters in the coating are acceptable and are usually due to absorption of hydrogen by the steel during the pickling process being expelled as a result of the heat put off by the galvanizing process.

4 General roughness and thick coatings: General roughness of the outer material is normally acceptable as long as not otherwise agreed on with the consumer. The cause of rough galvanized coatings is usually a result from uneven growth of zinc iron alloys because of the composition or surface condition of the steel.

5. Lumpiness and runs: Lumps are normally acceptable unless otherwise specified and are caused by uneven drainage. Lumps and runs have no impact on the coating life.

6. Pimples: Pimples are grounds for rejection depending on size and extent. Pimples are caused by inclusions of dross in the coating. Dross, which is a zinc iron alloy particles has a similar corrosion rate to the galvanized coating and its presence as finely dispersed pimples is not objectionable. Gross dross inclusions may be

grounds for rejection as they tend to embrittle the coating.

7. Bare spots: Bare spots are generally acceptable if small in area and suitably repaired, depending on the nature of the product. Some reasons for bare spots are faulty processing, rolling defects, laminations and nonmetallic impurities rolled into the surface.

8. Wet storage stain or bulky white deposit: A bulky white or gray deposit, known as wet storage stain may form on the surface of closely stacked freshly galvanized articles which become damp under poorly ventilated conditions during storage or were left damp as a result of the product not being dry before storing. reason for wet material being stored is an insufficient wax concentration, either to much was or to little.

Appearance

A galvanized coating is normally smooth, continuous and free from gross surface imperfections and inclusions. While the heavy zinc coating on general galvanized articles should be smooth and continuous it cannot be compared for surface smoothness to continuously galvanized sheet steel or wire since these are produced by processes which permit close control of coating thickness and appearance.

Differences in the lustre and colour of galvanized coatings do not significantly affect corrosion resistance and the presence or absence of spangle has no effect on coating performance. As discussed under ‘Dull grey coating’ below, uniform or patchy matt grey galvanized coatings give equal or better life than normal bright or spangled coatings. It is recommended that inspection of galvanized work should be carried out by a designated party at the galvanizer’s works in accordance with the following guidelines, and tested when

necessary as detailed under ‘Non-destructive testing for coating thickness’.

Variations in appearance and their relationship to coating quality Variations in appearance of galvanized coatings listed below and their influence on coating quality are discussed on following pages.

Dull grey coating

General comment: Acceptable. A dull grey appearance is caused by growth of the zinc-iron alloy layers through to the surface of the galvanized coating. Grey coatings may appear as localized dull patches or

lacework patterns on an otherwise normal galvanized coating or may extend over the entire surface.

Dull grey coatings usually occur on steels with relatively high silicon content which are highly reactive to molten zinc as discussed under ‘Composition of steel’.

Welds made with steel filler rods containing silicon may also produce localised grey areas in an otherwise normal galvanized coating.

Welds made with steel filler rods containing silicon may also produce localised grey areas in an otherwise normal galvanized coating.Dull grey coatings are often thicker than the normal bright or spangled coatings and therefore give longer life. It is rarely possible for the galvanizer to minimise or control the development of dull grey coatings which is dependent basically on steel composition.

Blisters

General comment: Small intact blisters acceptable.

Extremely rare. Small blisters in galvanized coatings are due to hydrogen absorbed by the steel during pickling being expelled as a result of the heat of the galvanizing process. Their occurrence is due to the nature of the steel and is outside the control of the galvanizer. Blisters do not reduce the corrosion resistance of the coating.

Rust staint

General comment: Acceptable when present as a surface stain. Rust staining on the surface of galvanized coatings is usually due to contact with or drainage from other corroded steel surfaces. Steel filings or saw-chips produced during erection and fabrication operations should be removed from galvanized surfaces to prevent possible localised rust staining. Rust staining may also be caused by the weeping of pickling acid from seams and joints causing damage to the galvanized coating, and in such cases requires a modification in design as discussed under ‘Overlapping surfaces’.

Rust staining on the surface of galvanized coatings is usually due to contact with or drainage from other corroded steel surfaces. Steel filings or saw-chips produced during erection and fabrication operations should be removed from galvanized surfaces to prevent possible localised rust staining. Rust staining may also be caused by the weeping of pickling acid from seams and joints causing damage to the galvanized coating, and in such cases requires a modification in design as discussed under ‘Overlapping surfaces’.A thin brown surface staining sometimes occurs in service when the galvanized coating comprises entirely zinc-iron alloys as discussed under ‘Dull grey coating’. Staining arises from corrosion of the iron content of the zinciron alloy coating and is therefore outside the control of the galvanizer. It has no effect on the corrosion resistance of th coating. Long term exposure testing has shown that the corrosion resistance of zinc-iron alloys is similar to that of normal galvanized coatings.

General roughness and thick coatings on welds.

General comment: Acceptable, unless otherwise agreed.

Rough galvanized coatings usually result from uneven growth of zinc-iron alloys because of the composition or surface condition of the steel. Where welding electrodes containing silicon have been used, the galvanized coating on the weld area may be thicker than normal and may also be brittle. Rough coatings of this type are usually thicker than normal and therefore provide longer protective life. General roughness may also be caused by over-pickling, prolonged immersion in the galvanizing bath, or excessive bath temperature, factors which are frequently dictated by the nature of the work and may be beyond the control of the

Rough galvanized coatings usually result from uneven growth of zinc-iron alloys because of the composition or surface condition of the steel. Where welding electrodes containing silicon have been used, the galvanized coating on the weld area may be thicker than normal and may also be brittle. Rough coatings of this type are usually thicker than normal and therefore provide longer protective life. General roughness may also be caused by over-pickling, prolonged immersion in the galvanizing bath, or excessive bath temperature, factors which are frequently dictated by the nature of the work and may be beyond the control of thegalvanizer. In architectural applications where a rough finish is aesthetically or functionally unacceptable, the steel composition and surface preparation should be closely specified and the galvanizer consulted at an early stage. It is rarely possible for the galvanizer to effect any later improvement.

Lumpiness and runs

General comment: Acceptable unless otherwise specified.

Australian/New Zealand Standard 4680 ‘Hot dip galvanized (zinc) coatings on fabricated ferrous articles’ demands that a galvanized coating shall be ‘smooth’ but points out that smoothness is a relative term and that coatings on fabricated articles should not be judged by the same standards as those applied to continuously galvanized products such as sheet steel and wire, since these are produced by processes which permit a high degree of control over coating thickness and appearance. Lumps and runs arising from uneven

drainage are not detrimental to coating life. When zinc drainage spikes are present on galvanized articles

drainage are not detrimental to coating life. When zinc drainage spikes are present on galvanized articlesand their size and position is such that there is a danger they may be knocked off in service removing the coating down to the alloy layers, they should be filed off by the galvanizer and, where necessary, the coating should be repaired as described. For architectural applications the galvanizer can sometimes

achieve a smoother finish than the normal commercial coating, depending on the shape and nature of the product. The steel should be carefully specified and the galvanizer consulted at the design stage and advised when the order is placed. Extra cost may be involved.

Pimples

General comment: May be grounds for rejection depending on size and extent.

General comment: May be grounds for rejection depending on size and extent.Pimples are caused by inclusions of dross in the coating. Dross, which comprises zinc-iron alloy particles, has a similar corrosion rate to the galvanized coating and its presence as finely dispersed pimples is not objectionable. Gross dross inclusions may be grounds for rejection as they tend to embrittle the coating.

Bare spots

General comment: Acceptable if small in area and suitably repaired, depending on the nature of the product.

Small localised flaws up to about 3 mm wide in a galvanized coating are usually self-healing because of the cathodic protection provided by the surrounding coating as discussed under Cathodic Protection .

They have little effect on the life of the coating. Australian/New Zealand Standard 4680 Appendix E

They have little effect on the life of the coating. Australian/New Zealand Standard 4680 Appendix E‘Renovation of damaged or uncoated areas’ specifies that “... the sum total of the damaged or uncoated areas shall not exceed 0.5% of the total surface area or 250cm2, whichever is the lesser, and no individual damaged or uncoated areas greater than 40cm2. However, as an exception, uncoated areas greater than 40cm2, which have been caused by unavoidable air locks during the galvanizing operation, shall be repaired.” Repair methods which accord with AS/NZS 4680 Appendix E are detailed.

Bare spots may be caused by under-preparation by the galvanizer and by a number of factors outside his control, and for which he cannot be responsible, including the presence of residual welding slags, rolling defects such as laps, folds and laminations in the steel, and non-metallic impurities rolled into the steel surface.

Wet storage stain or bulky white deposit

General comment: Not the galvanizer’s responsibility unless present before first shipment. Acceptable if non-adherent deposit is removed and the coating meets coating mass requirements. A bulky white or grey deposit, known as wet storage stain may form on the surface of closely stacked freshly galvanized

articles which become damp under poorly ventilated conditions during storage or transit. In extreme cases, the

protective value of the zinc coating may be seriously impaired but the attack is often very light despite the bulky appearance of the deposit. Initiation and development of wet storage staining on new

galvanized surfaces is readily prevented as detailed by attention to conditions of storage and transport and by

application of a chromate passivation treatment. Where the surface staining is light and smooth without

growth of the zinc oxide layer as judged by lightly rubbing fingertips across the surface, the staining will gradually disappear in service and blend in with the surrounding zinc surface as a result of normal weathering.

When the affected area will not be fully exposed in service, particularly on the underside of steelwork and in

condensation areas, or when it will be subject to a humid environment, wet storage staining must be removed as detailed below, even if it is superficial. Removal is necessary to allow formation of the basic zinc carbonate film which normally contributes to the corrosion resistance of galvanized

coatings. Medium to heavy buildup of white corrosion product must be removed to allow formation of a basic zinc carbonate film in service. Light deposits can be removed by brushing with a stiff bristle brush. Heavier deposits can be removed by brushing with a 5 percent solution of sodium or potassium dichromate with the addition of 0.1 percent by volume of concentrated sulphuric acid. This is applied with a stiff brush and left for about 30 seconds before thorough rinsing and drying. A check should be made to ensure that the coating

thickness in affected areas is not less than the minimum specified in relevant standards for the various classes of galvanized coatings as detailed. In extreme cases, where heavy white deposit or red rust has been allowed to form as a result of prolonged storage under poor conditions, corrosion products must be removed by thorough wire brushing and the damaged area repaired as detailed.

Dark spots/Flux staining

General comments: Acceptable if flux residues have been removed.

Smuts of dirt may be picked up on the surface of the galvanized coating from floors and trucks or from contact with other articles. These smuts are readily washed off to reveal a sound coating and are not harmful.

Where a flux blanket is used in the galvanizing process, stale flux may adhere to the surface of the work during immersion and appear as a black inclusion in the coating. Such inclusions tend to pick up moisture forming a corrosive solution and coatings containing them should be rejected. Black stains or deposits of flux picked up on the surface. the object is withdrawn from galvanizing the bath do not warrant rejection provided the underlying coating is sound and the deposit is removed.

Typical Steps in the manufacturing process of Galvanizing

1) Cleaning: The step in which the majority of oil, grease, and paints, are removed with a hot alkaline cleaner.

This cleaner usually consists of a lead bath or hot soapy water.

2) Rinse/Air Flow: A bath of cooled water to rinse any of the cleaning residue off and air knives to aid in the removing of any additional residue and water that were used on the material before entering the pickling system .

3) Pickling: A bath of diluted hydrochloric or sulfuric acid solutions that serve to remove surface rust and mill scale to provide a chemically clean metallic surface.

4) Rinse/Air Flow: Another water reservoir to dilute the acid concentration that may be left on the material before entering the flux stage and also an air knife to aid in removing un wanted residue.

5) Pre fluxing: The steel is immersed into a liquid flux to remove oxides and to prevent oxidation prior to entering the molten metal. The liquid flux is a concentration that consists usually of zinc ammonium chloride solution. The flux is the key ingredient in aiding in the ability of the zinc to adhere to the iron or steel.

6) Air Flow: Between the pre flux area and the molten metal the material is blown dry using a air knife to remove in moisture that consists prior to entering the liquid metal.

6) Air Flow: Between the pre flux area and the molten metal the material is blown dry using a air knife to remove in moisture that consists prior to entering the liquid metal.

7) Galvanizing: The item is immersed in a bath of molten zinc, with a temperature range between 820 and 850 degrees Fahrenheit. The temperature needs to be constantly in this range, if too cold, the zinc freezes, if too hot, the coating consistency is not symmetrical causing low coating, bare spots, or a burnt gray color to exist on galvanize. the material. With the temperature within range the zinc metallurgic ally bonds to the steel, creating a highly resistant zinc iron alloy layer. The zinc iron alloy is formed in the galvanizing process with pure zinc and the ferrous material being galvanized. This alloy layered is a bond between the iron that is diffused from the steel product being galvanized and the zinc in the molten stage. The layer of coating has several different phases of alloy layers with names such as Alpha, Gamma, Delta, Zeta, and the free Zinc layer. Each of these layers have a different amounts of iron, zinc ratio's. This alloy layer is dependent on the type of steel being used for the galvanizing process. These different alloy layers are what make up the weight of coating that the material receives, determining the finished gauge of the product. The layer gauge to be put on the material is determined by the time in which the material is actually in the zinc bath.

5) Pre fluxing: The steel is immersed into a liquid flux to remove oxides and to prevent oxidation prior to entering the molten metal. The liquid flux is a concentration that consists usually of zinc ammonium chloride solution. The flux is the key ingredient in aiding in the ability of the zinc to adhere to the iron or steel.

6) Air Flow: Between the pre flux area and the molten metal the material is blown dry using a air knife to remove in moisture that consists prior to entering the liquid metal.

6) Air Flow: Between the pre flux area and the molten metal the material is blown dry using a air knife to remove in moisture that consists prior to entering the liquid metal.7) Galvanizing: The item is immersed in a bath of molten zinc, with a temperature range between 820 and 850 degrees Fahrenheit. The temperature needs to be constantly in this range, if too cold, the zinc freezes, if too hot, the coating consistency is not symmetrical causing low coating, bare spots, or a burnt gray color to exist on galvanize. the material. With the temperature within range the zinc metallurgic ally bonds to the steel, creating a highly resistant zinc iron alloy layer. The zinc iron alloy is formed in the galvanizing process with pure zinc and the ferrous material being galvanized. This alloy layered is a bond between the iron that is diffused from the steel product being galvanized and the zinc in the molten stage. The layer of coating has several different phases of alloy layers with names such as Alpha, Gamma, Delta, Zeta, and the free Zinc layer. Each of these layers have a different amounts of iron, zinc ratio's. This alloy layer is dependent on the type of steel being used for the galvanizing process. These different alloy layers are what make up the weight of coating that the material receives, determining the finished gauge of the product. The layer gauge to be put on the material is determined by the time in which the material is actually in the zinc bath.

8) Finishing & Cooling: These two steps work together because the cooling of the material results in the finishing of the material. The finishing process consists of removing excess zinc by draining (to aid in the drainage coal and a hard wipe pad are sometimes used), vibrating, and for small items centrifuging (such as with a die in place that is sized according to the desired amount of coating gauge to be applied). While and directly after the finishing process is going on the material is rapidly cooled using different methods to include cold water, high pressure air knives that use nitrogen to form and cool the material. The cool water is aided by chillier units that decrease the temperature of the water before sending it to a quench tank where the material is directly cooled by immersing the completed material directly in the cold water. In many applications the product is also immersed in a wax based substance, applying a light coat to aid in the product being separated when at the end of the continuos run or in use later.

9) Inspection: The inspection process of galvanized material is the simplest and most important means of assessing the quality of the galvanized zinc coating. The inspection process uses some standard testing such as tensile strength, yield strength, hardness, elongation, stress/stain, form/condition, thermal conductivity, electrical resistance, coating weight/gauge, and most importantly the appearance of the finished product. The appearance of the galvanized coat demonstrates the relationship to the coating quality.

9) Inspection: The inspection process of galvanized material is the simplest and most important means of assessing the quality of the galvanized zinc coating. The inspection process uses some standard testing such as tensile strength, yield strength, hardness, elongation, stress/stain, form/condition, thermal conductivity, electrical resistance, coating weight/gauge, and most importantly the appearance of the finished product. The appearance of the galvanized coat demonstrates the relationship to the coating quality.

HOT DIP GALVANIZE

History of HDG

The recorded history of galvanizing goes back to 1742 when a French chemist named P.J. Malouin, in a presentation to the French Royal Academy, described a method of coating iron by dipping it in molten zinc. In 1836, Stanilaus Tranquille Modeste Sorel, another French chemist, obtained a patent for a means of coating iron with zinc, after first cleaning it with 9% sulfuric acid and fluxing it with ammonium chloride. A British patent for a similar process was granted in 1837. By 1850, the British galvanizing industry was using

10,000 tons of zinc a year for the protection of steel. Galvanizing is found in almost every major application and industry where iron or mild steel is used. The utilities, chemical process, pulp and paper, automotive, and transportation industries, to name just a few, historically have made extensive use of galvanizing for corrosion control. They continue to do so today. For over 150 years, hot-dip galvanizing has had a proven history of commercial success as a method of corrosion protection in myriad applications worldwide.

What is corrosion?

Corrosion is the reaction between a material and its environment that produces a deterioration of the material and alters its mechanical properties. The actual corrosion process that takes place on a piece of bare mild steel is very complex due to factors such as variations in the composition/structure of the steel, presence of impurities due to the higher instance of recycled steel, uneven internal stress, or exposure to a non-uniform environment.

It is very easy for microscopic areas of the exposed metal to become relatively anodic or cathodic. A large number of such areas can develop in a small section of the exposed metal. Further, it is highly possible that several different types of galvanic corrosion cells are present in the same small area of the actively corroding piece of steel. As the corrosion process progresses, the electrolyte may change due to materials dissolving

It is very easy for microscopic areas of the exposed metal to become relatively anodic or cathodic. A large number of such areas can develop in a small section of the exposed metal. Further, it is highly possible that several different types of galvanic corrosion cells are present in the same small area of the actively corroding piece of steel. As the corrosion process progresses, the electrolyte may change due to materials dissolving

in or precipitating from the solution. Additionally, corrosion products might tend to build up on certain areas of the metal. These corrosion products do not occupy the same position in the given galvanic series as the metallic component of their constituent element. As time goes by, there may be a change in the location of relatively cathodic or anodic areas and previously uncorroded areas of the metal are attacked and corrode. This eventually will result in uniform corrosion of the area. The rate at which metals corrode is controlled by factors such as electrical potential and resistance between anodic and cathodic areas, pH of the electrolyte, temperature and humidity.

How do you protect iron and steel from corrosion?

Barrier protection is perhaps the oldest and most widely used method of corrosion protection. It acts by isolating the metal from the electrolytes in the environment. Two important properties of barrier protection are adhesion to the base metal and abrasion resistance.

Cathodic protection is an equally important method for preventing corrosion. Cathodic protection requires changing an element of the corrosion circuit, introducing a new corrosion element, and ensuring that the base metal becomes the cathodic element of the circuit. Hotdip galvanizing provides excellent barrier and cathodic protection. The sacrificial anode method, in which a metal or alloy that is anodic to the metal to be protected is placed in the circuit and becomes the anode. The protected metal becomes the cathode and does not corrode. The anode corrodes, thereby providing the desired sacrificial protection. In nearly all electrolytes encountered in everyday use, zinc is anodic to iron and steel. Thus, the galvanized coating provides cathodic corrosion protection as well as barrier protection.

Service-Life Chart for Hot-Dip Galvanized Coatings

Continous and Batch Galvanize

These completely different methods of applying galvanized coatings produce different types of coatings.

There are 4 main differences that impact on anti-corrosion performance of BATCH galvanized steel compared to CONTINUOUSLY galvanized steel. These are:

1. Coating thickness - BATCH galvanized items of the same section thickness are typically at least 3 TIMES thicker than similar CONTINUOUSLY galvanized coatings on sheet and tube.

2. Coating hardness - BATCH galvanized items have much thicker zinc/iron alloy layers in the coatings which gives BATCH galvanized items 5 TIMES the abrasion resistance of CONTINUOUSLY galvanized coatings.

3. Coating integrity - BATCH galvanized coatings apply a uniform heavy coating to all internal and external surfaces, edges and cavities. CONTINUOUSLY galvanized coating will always have exposed bare steel at cut edges. CONTINUOUSLY galvanized hollow sections are fully galvanized on the external surfaces only.

4. Coating mass - The cathodic protection of exposed steel by zinc depends of the mass of the zinc in relation to the area of exposed steel. Because of the drainage characteristics of BATCH galvanized coatings, the coating mass on BATCH galvanized products is significantly higher (typically 3-5 times) in proportion to thickness than CONTINUOUSLY galvanized coatings. Hot rolled medium structural sections commonly achieve coating mass levels exceeding 1000 g/m2.

MORE COATING THICKNESS = LONGER COATING LIFE

150 years of field testing has determined that all things being equal, galvanized coating life is equivalent to galvanized coating thickness. When comparing BATCH galvanized coatings to CONTINUOUSLY galvanized coating, all things are not equal.

THE CUT EDGE FACTOR

All CONTINUOUSLY galvanized sections have exposed steel at cut edges and rely on the adjacent zinc in the coating to provide cathodic protection to the bare steel. This requirement accelerates the rate of corrosion of the galvanized coating at cut edges. The thicker the CONTINUOUSLY galvanized section, the faster the rate of coating corrosion at cut edges because of the greater area of bare steel exposed. Even if it was possible to apply a CONTINUOUSLY galvanized coating to a steel item to the same thickness as a BATCH galvanized item, the cut edge factor gives the BATCH galvanized coating a life typically 1.5 TIMES greater.

COMPARISON OF GALVANIZED COATINGS

CONTINUOUSLY galvanized coatings comply very closely to their specified coating mass. BATCH

galvanized coatings on hot rolled steel sections almost always exceed their minimum specified coating

mass.

The recorded history of galvanizing goes back to 1742 when a French chemist named P.J. Malouin, in a presentation to the French Royal Academy, described a method of coating iron by dipping it in molten zinc. In 1836, Stanilaus Tranquille Modeste Sorel, another French chemist, obtained a patent for a means of coating iron with zinc, after first cleaning it with 9% sulfuric acid and fluxing it with ammonium chloride. A British patent for a similar process was granted in 1837. By 1850, the British galvanizing industry was using

10,000 tons of zinc a year for the protection of steel. Galvanizing is found in almost every major application and industry where iron or mild steel is used. The utilities, chemical process, pulp and paper, automotive, and transportation industries, to name just a few, historically have made extensive use of galvanizing for corrosion control. They continue to do so today. For over 150 years, hot-dip galvanizing has had a proven history of commercial success as a method of corrosion protection in myriad applications worldwide.

What is corrosion?

Corrosion is the reaction between a material and its environment that produces a deterioration of the material and alters its mechanical properties. The actual corrosion process that takes place on a piece of bare mild steel is very complex due to factors such as variations in the composition/structure of the steel, presence of impurities due to the higher instance of recycled steel, uneven internal stress, or exposure to a non-uniform environment.

It is very easy for microscopic areas of the exposed metal to become relatively anodic or cathodic. A large number of such areas can develop in a small section of the exposed metal. Further, it is highly possible that several different types of galvanic corrosion cells are present in the same small area of the actively corroding piece of steel. As the corrosion process progresses, the electrolyte may change due to materials dissolving

It is very easy for microscopic areas of the exposed metal to become relatively anodic or cathodic. A large number of such areas can develop in a small section of the exposed metal. Further, it is highly possible that several different types of galvanic corrosion cells are present in the same small area of the actively corroding piece of steel. As the corrosion process progresses, the electrolyte may change due to materials dissolvingin or precipitating from the solution. Additionally, corrosion products might tend to build up on certain areas of the metal. These corrosion products do not occupy the same position in the given galvanic series as the metallic component of their constituent element. As time goes by, there may be a change in the location of relatively cathodic or anodic areas and previously uncorroded areas of the metal are attacked and corrode. This eventually will result in uniform corrosion of the area. The rate at which metals corrode is controlled by factors such as electrical potential and resistance between anodic and cathodic areas, pH of the electrolyte, temperature and humidity.

How do you protect iron and steel from corrosion?

Barrier protection is perhaps the oldest and most widely used method of corrosion protection. It acts by isolating the metal from the electrolytes in the environment. Two important properties of barrier protection are adhesion to the base metal and abrasion resistance.

Cathodic protection is an equally important method for preventing corrosion. Cathodic protection requires changing an element of the corrosion circuit, introducing a new corrosion element, and ensuring that the base metal becomes the cathodic element of the circuit. Hotdip galvanizing provides excellent barrier and cathodic protection. The sacrificial anode method, in which a metal or alloy that is anodic to the metal to be protected is placed in the circuit and becomes the anode. The protected metal becomes the cathode and does not corrode. The anode corrodes, thereby providing the desired sacrificial protection. In nearly all electrolytes encountered in everyday use, zinc is anodic to iron and steel. Thus, the galvanized coating provides cathodic corrosion protection as well as barrier protection.

Service-Life Chart for Hot-Dip Galvanized Coatings

Continous and Batch Galvanize

There are many types of coatings that are specified as hot dip galvanized. The process involves immersing steel in molten zinc. The zinc reacts with the steel to form the galvanized coatings. The time the steel is immersed in the zinc along with post-galvanizing treatment controls the coating thickness, appearance and other characteristics

Hot dip galvanized coatings are applied to steel to improve the anti-corrosion performance of the steel to ensure that it lasts as long as possible with a minimum of maintenance. Standards currently being developed for the housing industry have set a benchmark of at least 50 years as the acceptable life of structural building products. Only hot dip galvanized steel products with the heaviest galvanized coatings are capable of meeting this requirement.

The Australian Standard AS 4680 - 1999 , Hot Dipped Galvanized Coatings on Ferrous Articles, includes galvanized coating standards on sheet, wire, tube and general articles. A great deal of confusion exists through the inclusion of galvanized coatings with significantly different coating characteristics within the same Australian Standard.

Hot dip galvanized coatings are applied to steel to improve the anti-corrosion performance of the steel to ensure that it lasts as long as possible with a minimum of maintenance. Standards currently being developed for the housing industry have set a benchmark of at least 50 years as the acceptable life of structural building products. Only hot dip galvanized steel products with the heaviest galvanized coatings are capable of meeting this requirement.

The Australian Standard AS 4680 - 1999 , Hot Dipped Galvanized Coatings on Ferrous Articles, includes galvanized coating standards on sheet, wire, tube and general articles. A great deal of confusion exists through the inclusion of galvanized coatings with significantly different coating characteristics within the same Australian Standard.

COATING THICKNESS COUNTS

All sheet, wire and many tube products are CONTINUOUSLY galvanized. This means that the coating is applied at high speed and the coating thickness is controlled by the process. Immersion time in the zinc is measured in seconds. Alternatively, in the BATCH hot dip galvanizing process steel items are immersed for periods ranging from 3-10 minutes, depending on the mass of the items being galvanized.These completely different methods of applying galvanized coatings produce different types of coatings.

There are 4 main differences that impact on anti-corrosion performance of BATCH galvanized steel compared to CONTINUOUSLY galvanized steel. These are:

1. Coating thickness - BATCH galvanized items of the same section thickness are typically at least 3 TIMES thicker than similar CONTINUOUSLY galvanized coatings on sheet and tube.

2. Coating hardness - BATCH galvanized items have much thicker zinc/iron alloy layers in the coatings which gives BATCH galvanized items 5 TIMES the abrasion resistance of CONTINUOUSLY galvanized coatings.

3. Coating integrity - BATCH galvanized coatings apply a uniform heavy coating to all internal and external surfaces, edges and cavities. CONTINUOUSLY galvanized coating will always have exposed bare steel at cut edges. CONTINUOUSLY galvanized hollow sections are fully galvanized on the external surfaces only.

4. Coating mass - The cathodic protection of exposed steel by zinc depends of the mass of the zinc in relation to the area of exposed steel. Because of the drainage characteristics of BATCH galvanized coatings, the coating mass on BATCH galvanized products is significantly higher (typically 3-5 times) in proportion to thickness than CONTINUOUSLY galvanized coatings. Hot rolled medium structural sections commonly achieve coating mass levels exceeding 1000 g/m2.

MORE COATING THICKNESS = LONGER COATING LIFE

150 years of field testing has determined that all things being equal, galvanized coating life is equivalent to galvanized coating thickness. When comparing BATCH galvanized coatings to CONTINUOUSLY galvanized coating, all things are not equal.

THE CUT EDGE FACTOR

All CONTINUOUSLY galvanized sections have exposed steel at cut edges and rely on the adjacent zinc in the coating to provide cathodic protection to the bare steel. This requirement accelerates the rate of corrosion of the galvanized coating at cut edges. The thicker the CONTINUOUSLY galvanized section, the faster the rate of coating corrosion at cut edges because of the greater area of bare steel exposed. Even if it was possible to apply a CONTINUOUSLY galvanized coating to a steel item to the same thickness as a BATCH galvanized item, the cut edge factor gives the BATCH galvanized coating a life typically 1.5 TIMES greater.

COMPARISON OF GALVANIZED COATINGS

CONTINUOUSLY galvanized coatings comply very closely to their specified coating mass. BATCH

galvanized coatings on hot rolled steel sections almost always exceed their minimum specified coating

mass.

VENTING AND DRAINING - HOW TO GET THE HOLE SIZE RIGHT

One of the most common issues in designing fabrications for hot dip galvanizing is ensuring that fabrications are vented and drained correctly. All steel to be galvanized needs to be immersed in molten zinc and the zinc needs to be able to flow freely into and out of all hollow sections and corners. The flow of molten zinc into, off, and out of the fabrication is one of the most important factors in determining the final quality of the coating. Inadequate venting and draining can cause the following galvanized coating defects:

• misses in the coating caused by air locks preventing molten zinc contacting the steel surface.

• puddling of zinc in corners, wasting zinc and interfering with subsequent assembly

• ash trapped on zinc surface causing surface defects

• irregularities in surface appearance caused by erratic immersion and withdrawal because of item floating or trapping zinc internally

• thick zinc runs on surface caused by zinc freezing during draining

• steel is only about 15% heavier than zinc. A relatively small amount of air trapped inside a hollow section will prevent the section from sinking in the molten zinc

• any water trapped inside a hollow section will expand 1750 times its original volume as steam and generate pressures as high as 50 MPa (7250 psi).

BASIC VENTING RULES

• no vent hole should be smaller than 8 mm

smaller than 8 mm

• the preferred minimum size is 12 mm

• about 200 grams of zinc ash will be produced for each square metre of steel surface galvanized.

This ash is a solid powder and will not pass through small openings. Venting large internal areas required larger vent holes to allow ash to escape

• hollow vessels require 1250 mm2 of vent hole for each cubic metre of enclosed volume. This

means that a 40 mm2 diameter hole is required for each cubic metre of volume

• hollow sections such as tube, RHS and SHS require minimum vent hole area equivalent to 25% of the section’ diagonal cross section

• vent holes should be at the edges of hollow sections

BASIC DRAINING RULES

• no drain hole should be less than 10 mm

• preferred minimum drain hole size is 25 mm

• large hollow sections ( tan ks, pressure vessels) require a 100 mm diameter drain hole for each

ks, pressure vessels) require a 100 mm diameter drain hole for each

cubic metre of enclosed volume

• drain holes should be at the edges of hollow sections.

• hollow sections such as tube, RHS and SHS require minimum drain hole area equivalent to 25% of the section’ diagonal cross section. The preferred design option is to leave the ends of tubes, RHS and SHS open.

• misses in the coating caused by air locks preventing molten zinc contacting the steel surface.

• puddling of zinc in corners, wasting zinc and interfering with subsequent assembly

• ash trapped on zinc surface causing surface defects

• irregularities in surface appearance caused by erratic immersion and withdrawal because of item floating or trapping zinc internally

• thick zinc runs on surface caused by zinc freezing during draining

• steel is only about 15% heavier than zinc. A relatively small amount of air trapped inside a hollow section will prevent the section from sinking in the molten zinc

• any water trapped inside a hollow section will expand 1750 times its original volume as steam and generate pressures as high as 50 MPa (7250 psi).

BASIC VENTING RULES

• no vent hole should be

smaller than 8 mm

smaller than 8 mm• the preferred minimum size is 12 mm

• about 200 grams of zinc ash will be produced for each square metre of steel surface galvanized.

This ash is a solid powder and will not pass through small openings. Venting large internal areas required larger vent holes to allow ash to escape

• hollow vessels require 1250 mm2 of vent hole for each cubic metre of enclosed volume. This

means that a 40 mm2 diameter hole is required for each cubic metre of volume

• hollow sections such as tube, RHS and SHS require minimum vent hole area equivalent to 25% of the section’ diagonal cross section

• vent holes should be at the edges of hollow sections

BASIC DRAINING RULES

• no drain hole should be less than 10 mm

• preferred minimum drain hole size is 25 mm

• large hollow sections ( tan

ks, pressure vessels) require a 100 mm diameter drain hole for each

ks, pressure vessels) require a 100 mm diameter drain hole for eachcubic metre of enclosed volume

• drain holes should be at the edges of hollow sections.

• hollow sections such as tube, RHS and SHS require minimum drain hole area equivalent to 25% of the section’ diagonal cross section. The preferred design option is to leave the ends of tubes, RHS and SHS open.

Langganan:

Postingan (Atom)