INTRODUCTION

A common phenomenon with hot dip galvanized structural steel is the grey appearance of part or all of the coating after galvanizing, where the expectation of the customer is for the galvanized steel to be shiny. Grey coatings are often a cause of contention between galvanizers and their customers as a result. This File has been produced to explain the phenomenon of grey coatings, their cause and effect on the performance of hot dip galvanized steel.

WHY ARE SOME GALVANIZED COATINGS GREY

Hot dip galvanized coatings are the result of a metallurgical reaction between the zinc and the steel. This

reaction forms a series of zinc-iron alloys in the form of needle like crystals that grow from the steel’s

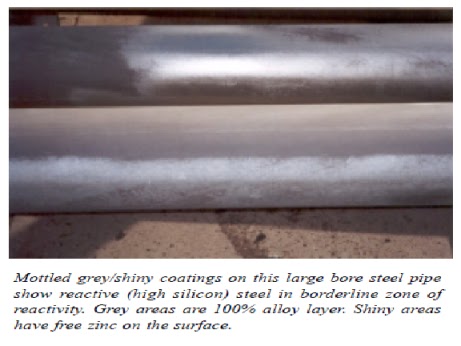

surface. With conventional galvanized coatings, the alloy layer makes up about 80% of the coating and the upper 20% of the coating is zinc. This surface layer gives produced the shiny appearance. Where this surface coating of free zinc is not present, the zinc-iron crystals are visible and it is the appearance of these that gives the coating matte silver or grey appearance. When the steel emerges from the galvanizing bath, the coating is always shiny. The appearance of the coating changes to grey as the residual heat from the galvanizing process allows the reaction between the steel and the zinc to continue until all the fee zinc on the surface is consumed, leaving the coating with 100% alloy layers.

WHAT CAUSES SOME STEELS TO PRODUCE GREY COATINGS?

The reaction between zinc and steel in the galvanizing process is a function of a number of factors. The

most significant of these with respect to grey coatings are:

1. The chemical composition of the steel

2. The steel section thickness

3. The galvanizing bath temperature

4. The cooling rate of the steel after galvanizing

Of these, the chemical composition of the steel is the most important. Two alloying elements in particular, silicon and phosphorus, will increase the reaction rate of the zinc with the steel. If the silicon content exceeds 0.20% or the combination of the percentage of silicon plus 2x the phosphorus level exceeds 0.25%, then the likelihood of grey coatings forming is increased. Most Australian-made steels are ‘galvanizer friendly’ in this respect with silicon and phosphorus levels controlled within acceptable limits. As about 35% of steel used in Australia is now imported, the variation in steel chemistry makes control of grey coatings a more difficult issue. The steel section thickness is a factor with relatively thick sections (over 20 mm) because the greater mass of steel retains heat longer. The zinc-iron reaction will continue even when the zinc has solidified (at 420 degrees C) as a solid-state reaction until the temperature falls below about 390 degrees C. For this reason, heavy plate fabrications will produce thicker, grey coatings regardless of the steel chemistry. The galvanizing bath temperature will only have an effect where it is possible to operate the galvanizing bath at above the normal 455 degrees C level. This can only be done in special ceramic lined galvanizing baths, as high operating temperatures will damage conventional steel galvanizing baths. The cooling rate of the steel after galvanizing can affect the coating appearance. Galvanized items that are air-cooled are more likely to develop grey or partly grey coating than items that are quenched immediately after withdrawal from the galvanizing bath. This occurs because the quenching halts the solid-state zinc iron reaction before all the free-zinc on the coating’s surface is consumed.

WHAT EFFECT DO GREY COATINGS HAVE ON COATING PERFORMANCE

Without exception, grey coatings are thicker than shiny galvanized coatings on equivalent steel sections. Australian and international galvanizing standards require that on structural sections over 6 mm in thickness, the minimum galvanized coating thickness is specified at 85 microns. Grey galvanized coatings are more typically almost double this thickness, and on heavier sections will frequently exceed 200 microns in thickness. As galvanized coating life is almost directly proportional to coating thickness, a significant increase in service life can be expected from these heavier coatings. The main problems associated with grey coatings are their aesthetic acceptability and the fact that the zinc-iron alloy layers are hard and inflexible, and may be prone to mechanical damage if subjected to impacts during transport and erection, where conventional shiny coatings have excellent resistance to quite severe impacts. One fringe benefit of grey coatings on galvanized steel is that they provide a good substrate for painting, because of the matte surface. BHP produces a galvanized sheet product called Zincanneal where the mill produced shiny galvanized coating is converted to a 100% alloy layer coating by post heat treatment to improve the paintability of the product for whitegoods manufacture.

Good to see this helpful information here, Thanks for sharing with us....

BalasHapusZinga Galvanising Paint